.png)

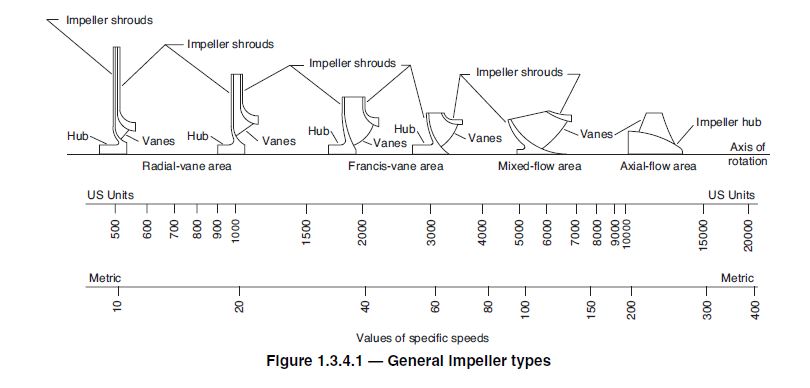

Classification by Specific Speed

Specific Speed (ns) - Specific speed is an index of pump performance at the pump's best efficiency point (BEP) rate of flow, with the maximum diameter impeller, and at a given rotative speed. Specific speed is used for many design purposes including efficiency prediction and classifying the relative discharge of an impeller as radial, mixed or axial and expressed by the following equation: Specific Speed Equation.

Radial flow – Pumps of this type with single inlet impellers usually have a specific speed below approximately 90 (4500) and, with double suction impellers, a specific speed below approximately 135 (7000). This type is commonly referred to as a centrifugal pump. In In centrifugal pumps the liquid enters the impeller at the hub and flows radially to the periphery, exiting perpendicular to the rotating shaft. - Figure 1.1.4.2

Mixed flow - This type of pump has a single inlet impeller where the flow enters axially and discharges in a mixed axial and radial direction. Pumps of this type usually have a specific speed from approximately 90 (4500) to 200 (10,000). - Figure 1.1.4.3

Axial flow - A pump of this type, sometimes called a propeller pump, has a single inlet impeller with the flow entering axially and discharging nearly axially. Pumps of this type usually have a specific speed above approximately 200 (10,000). - Figure 1.1.4.4

Pump Definitions and Nomenclature:

- Head (h) [H]– Head is the expression of the energy content of a liquid in reference to an arbitrary datum. It is expressed in units of energy per unit weight of liquid. The measuring unit for head is meters (feet) of liquid.

- Total head (H) [Htx]– This is the measure of energy increase, per unit weight of liquid, imparted to the liquid by the pump, and is the difference between total discharge head and total suction head. This is the head normally specified for pumping applications because the complete characteristics of a system determine the total head required.

- Rate of flow [Q]– The rate of flow of a pump is the total volume throughput per unit of time at suction conditions. The term capacity is also used.

- Best Efficiency Point (BEP)– The rate of flow and total head at which the pump efficiency is maximum at a given speed and impeller diameter.

- Displacement (D)– For a positive displacement pump it is the theoretical volume per revolution of the pump shaft. Calculation methods and terminology may differ between different types of positive displacement pumps.

- Net Positive Suction Head Available (NPSHA)– NPSHA is determined by the conditions of the installation and is the total suction head of liquid absolute, determined at the first-stage impeller datum minus the absolute vapor pressure in meters (feet) of the liquid at a specific rate of flow expressed in meters (feet) of liquid. Note that for positive displacement pumps the term Net Positive Inlet Pressure Available (NPIPA) is used and is expressed in pressure absolute kPa (psi).

- Net Positive Suction Head Required (NPSHR)– NPSHR is the minimum NPSH given by the manufacturer/supplier for a pump achieving a specified performance at the specified capacity, speed, and pumped liquid. Note that occurrence of visible cavitation, increase of noise and vibration due to cavitation, beginning of head or efficiency drop, and cavitation erosion can occur when margin above NPSHr is present. Note that for positive displacement pumps the term Net Positive Inlet Pressure Required (NPIPR) is expressed in pressure absolute kPa (psi).

- Net Positive Suction Head 3% (NPSH3)– For rotodynamic pumps NPSH3 is defined as the value of NPSHR at which the first-stage total head drops by 3% due to cavitation. This is determined by the vendor by testing with water as outlined in. ANSI/HI 14.6 Rotodynamic Pumps for Hydraulic Performance Acceptance Tests

- Suction specific speed (S)– Suction specific speed is an index of pump suction operating characteristics. It is determined at the BEP rate of flow with the maximum diameter impeller. Suction specific speed is an indicator of the net positive suction head required [NPSH3] for given values of capacity and also provides an assessment of a pump's susceptibility to internal recirculation. Suction specific speed is expressed by the following equation: Suction Specific Speed

- Impeller - The bladed member of a rotating assembly of the pump which imparts the prinicpal force to the liquid pumped.